Depuis sa création en 2002, Zhangjiagang SMK MFG. Co., Ltd. a spécialisé dans les produits de sécurisation et de contrôle de fret, avec plus 20 ans d'expérience en R&D et en exportation mondiale. L'entreprise est un fabricant en Chine de Arrimage industriel et une Fournisseurs personnalisés de Arrimage industriel, et exploite trois usines ainsi qu'un centre d'entrepôt à grande échelle, formant un réseau d'approvisionnement international efficace.

La gamme de produits de SMK comprend des sangles d'attachement, des cordons élastiques, des sangles de remorquage, des élingues de levage, des palans et des accessoires 4x4, largement utilisés dans les secteurs de transport, de logistique, de plein air et industriel. Sa marque interne XStrap jouit d'une forte reconnaissance sur les marchés mondiaux, aux côtés de flexible Services OEM / ODM pour les besoins personnalisés.

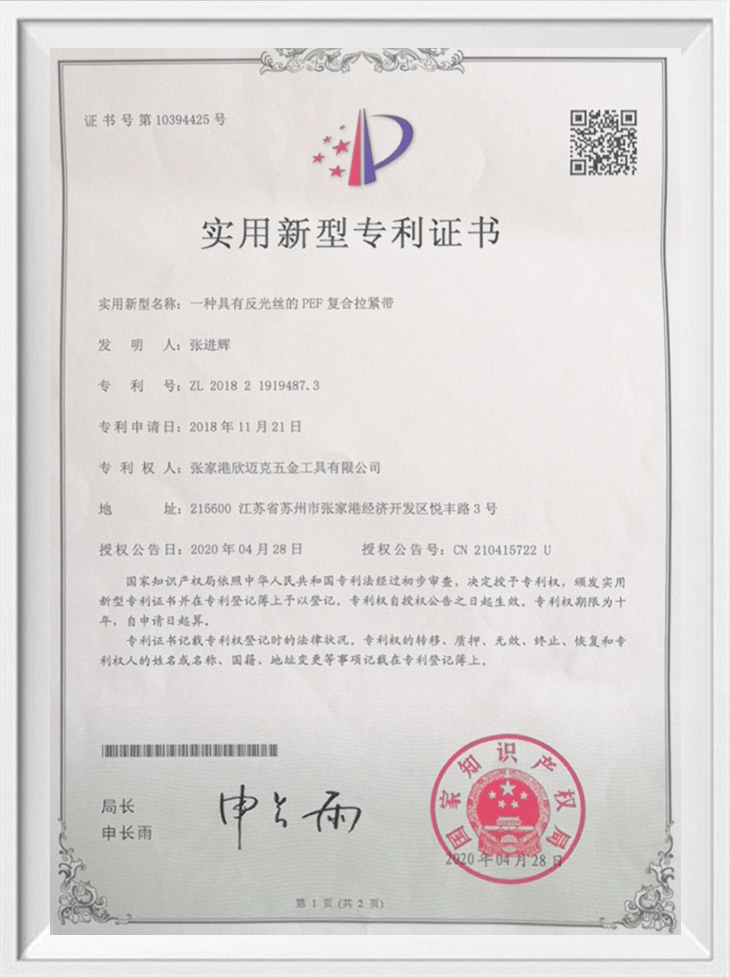

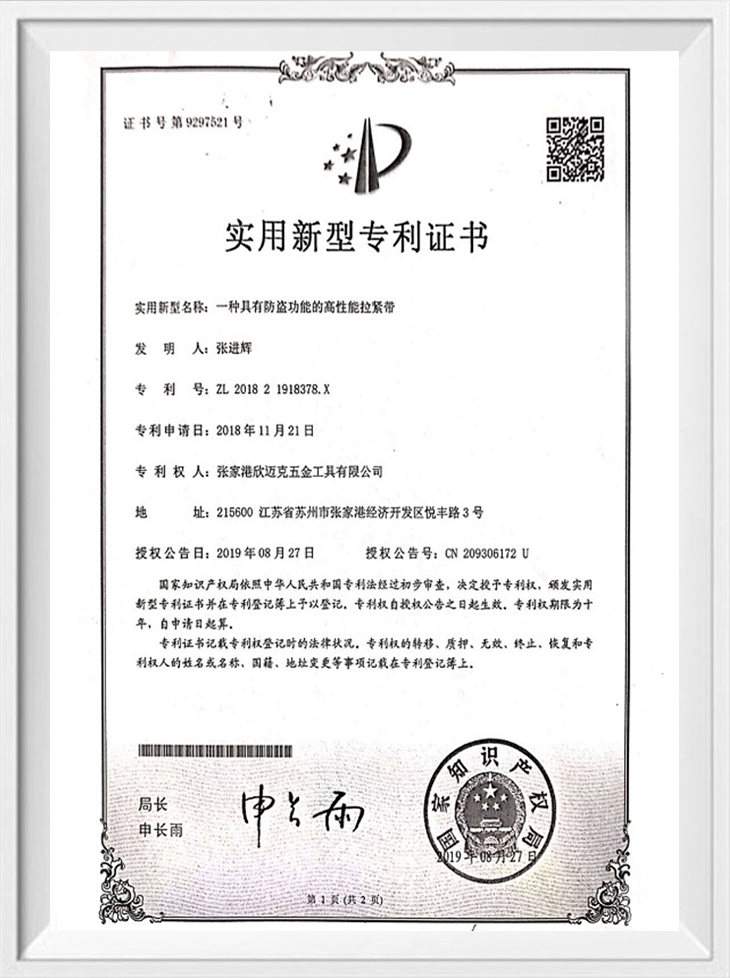

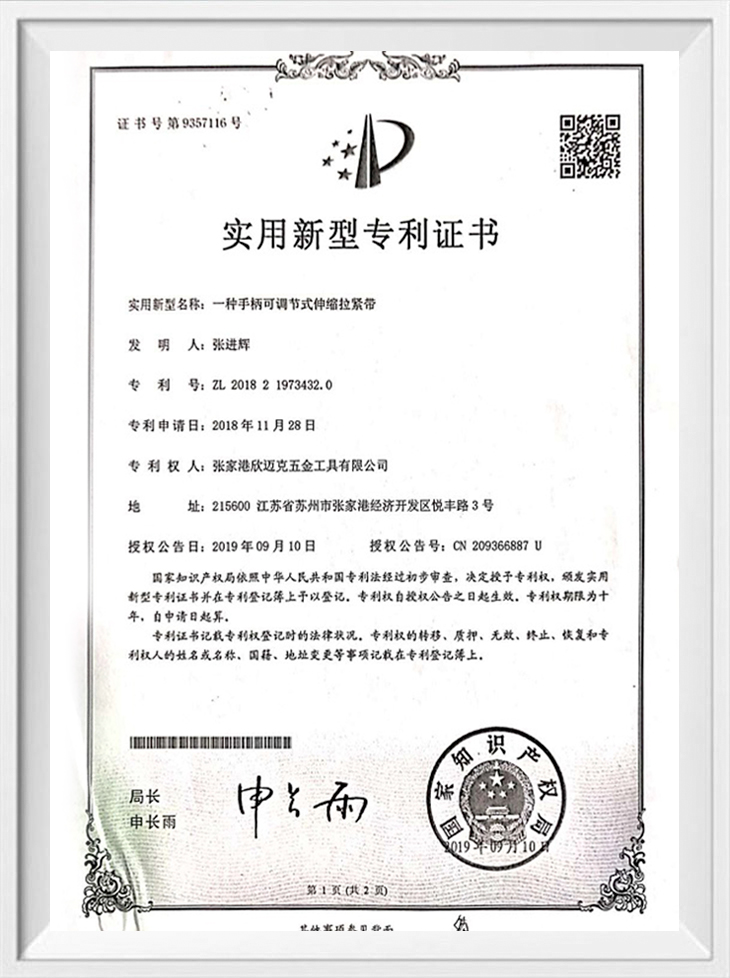

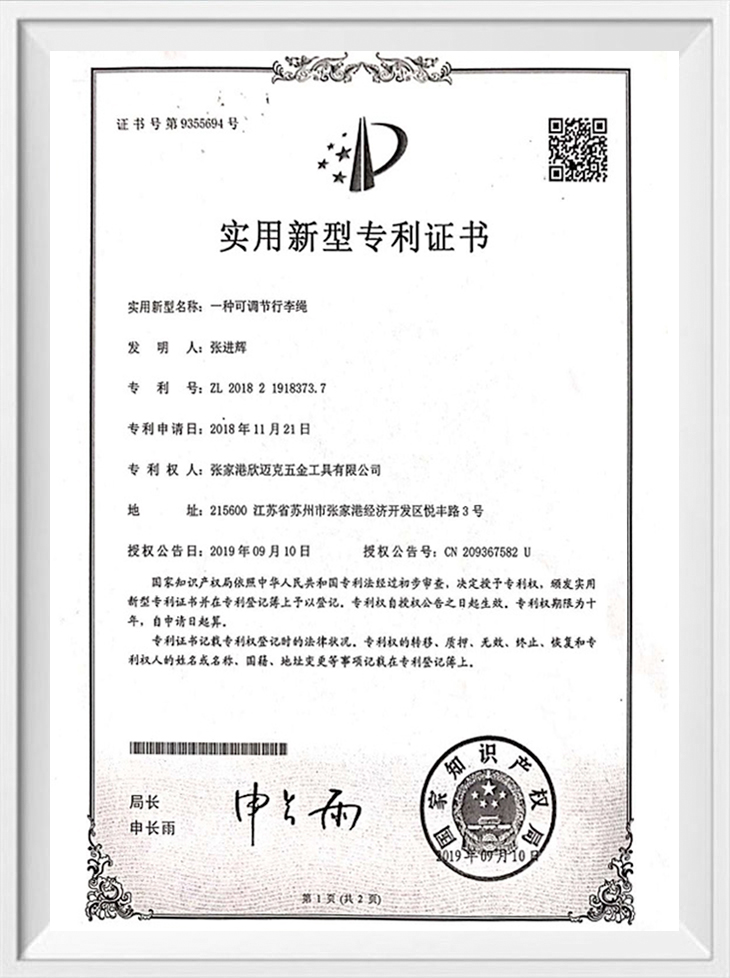

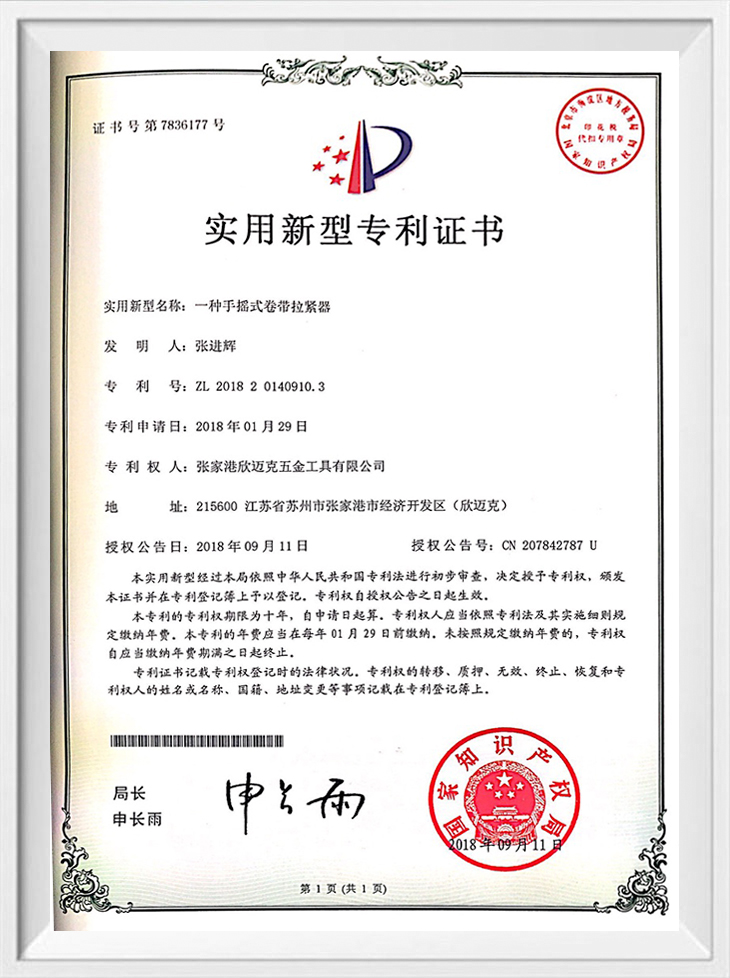

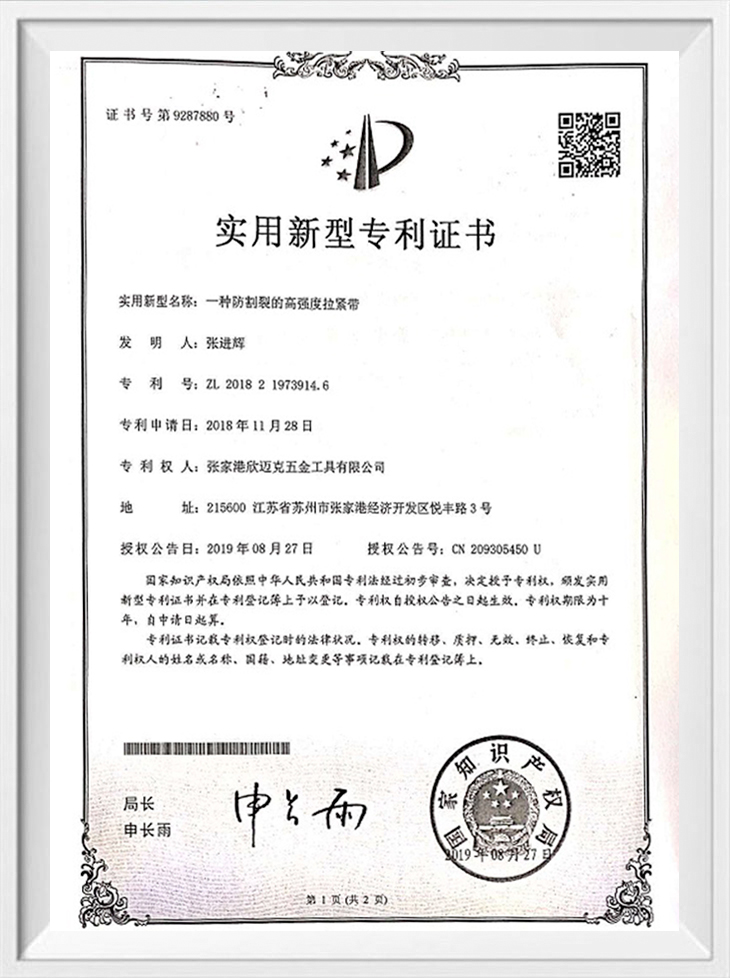

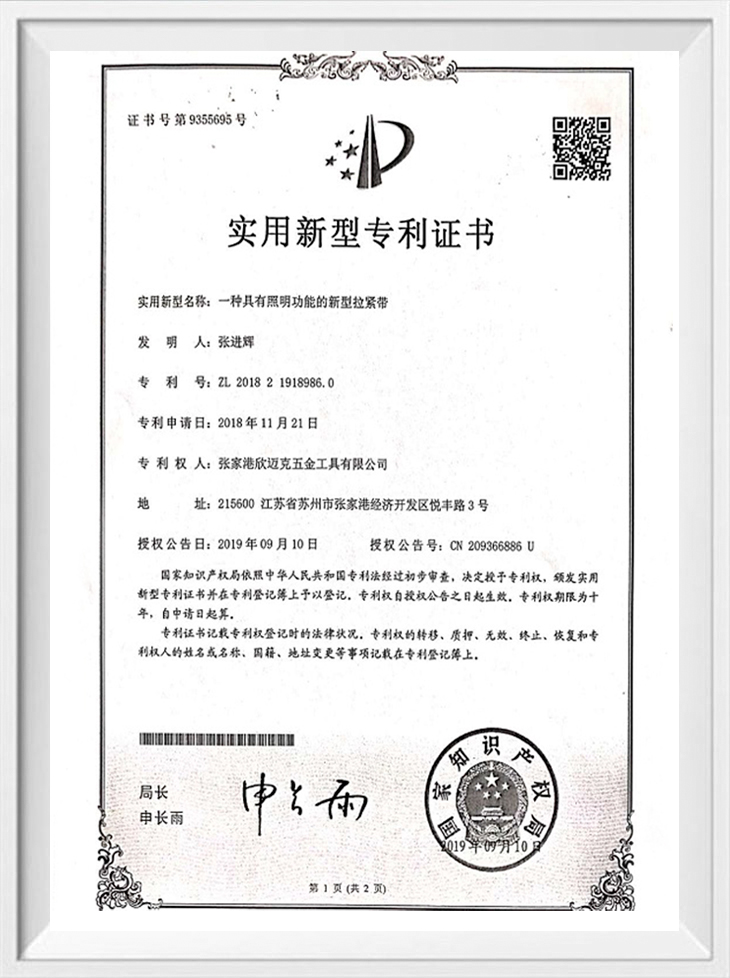

Avec plus de 8 000 m² d'espace de production, SMK est équipé de lignes automatisées avancées et de laboratoires de tests internes, assurant un contrôle de qualité complet des matières premières aux produits finis. La société est certifiée ISO 9001, Smeta audité et a passé des inspections antiterroristes C-TPAT et plusieurs certifications GS et brevets.

Pour l'avenir, SMK continuera de mettre à niveau ses systèmes de contrôle des cargaisons, de rester proches des besoins des clients et de fournir des produits et services efficaces de haute qualité dans le monde.

Produit

-

Nouveaux produits

- Solutions de plateau lisse

- Solutions pour l'intérieur de fourgon

-

Cordon d'arrimage et élastique polyvalent

-

Promotion d'arrimage à cliquet

-

Arrimage industriel

-

Arrimage de moto industrielle

-

Attache industrielle pour VTT UTV

-

Arrimage industriel en acier inoxydable

-

Attache de tente industrielle

-

Sangles de bateau

-

Sangle De Fixation À Cliquet À Charge Légère

-

Sangle De Fixation À Cliquet À Charge Standard

-

Sangle De Fixation À Cliquet À Charge Lourde

-

Sangle De Fixation À Cliquet À Charge Extra-Lourde

-

Cordon élastique

-

Promotion d'arrimage à cliquet

-

Solutions de transport et de remorquage de véhicules

-

Sangles De Transport De Véhicules

-

Sangles d'arrimage de voiture

-

Sangle de rechange pour arrimage de voiture

-

Sangles de panier de chariot de remorquage

-

Filets de roue

-

Sangles de récupération

-

Sangles et cordes de remorquage

-

Sangle de remorquage à cliquet et sangle de remorquage V Bridle

-

Extracteur et accessoires de remorquage Come Along

-

Sangles De Transport De Véhicules

-

Sangle

- Matériel d'arrimage

-

Attache et cordon élastique certifiés TUV&GS

-

Remorquage et gréement

-

4×4 tout-terrain et remorques

Vente en gros et fabrication de Arrimage industriel de qualité grand public

Informations à mettre à jour

-

Face à la demande toujours croissante du marché, Xstrap Company a toujours maintenu un rythme d'expédition très efficace, garantissant les besoins des clients ave...

EN SAVOIR PLUS -

CCBEC(China (Shenzhen) Cross-Border E-Commerce Fair) is currently one of the largest and most influential professional exhibitions in the field of cross-border e-co...

EN SAVOIR PLUS -

Verified Supplier is the highest level membership on Alibaba.com. The platform conducts comprehensive verification—through both online document review and on-site f...

EN SAVOIR PLUS

Les fondements de la sécurité du fret : définition fondamentale et valeur de l’arrimage industriel

Dans les domaines de la logistique lourde, de la construction et du commerce maritime, la sécurité des marchandises dépend entièrement du « lien » reliant les marchandises à la plate-forme de transport. Un Arrimage industriel est bien plus qu’une simple corde ou sangle ; il s'agit d'un système de sécurité de précision conçu pour gérer d'immenses forces. Depuis sa création en 2002, Zhangjiagang SMK MFG. Co., Ltd. s'est spécialisé dans le secteur de l'arrimage et du contrôle des marchandises. Avec plus de 20 ans d'expérience en R&D et en exportation mondiale, l'entreprise exploite trois usines et un centre d'entrepôt à grande échelle, garantissant que chaque Arrimage industriel est fabriqué pour protéger les actifs dans des conditions extrêmes.

Sélection d'un Arrimage industriel qui répond à des normes industrielles rigoureuses est au cœur de la prévention des accidents logistiques. Dans la mécanique complexe du transport, les marchandises sont soumises non seulement à la gravité statique, mais aussi à des impacts dynamiques massifs dus au freinage, aux virages et aux vibrations de la route. Ces forces peuvent souvent représenter plusieurs fois le poids statique de la charge. Zhangjiagang SMK MFG. Co., Ltd. opère dans un espace de production de 8 000 m² équipé de lignes automatisées avancées pour garantir chaque Arrimage industriel reste stable sous ces contraintes. Sa marque interne XSTRAP bénéficie d'une forte reconnaissance sur les marchés mondiaux, ainsi que de services OEM/ODM flexibles pour des besoins personnalisés.

Mécanique physique et indicateurs de sécurité

Pour comprendre les performances d'un Arrimage industriel , il faut maîtriser deux paramètres essentiels :

- Limite de charge de travail (CMU) : C'est le poids maximum d'un Arrimage industriel est autorisé à prendre en charge pendant le fonctionnement normal. Il sert de référence principale aux ingénieurs lors de la conception de plans de sécurisation.

- Résistance à la rupture (BS) : C'est à ce moment-là que le système tombe en panne physiquement lors des tests en laboratoire. Les normes industrielles exigent généralement un facteur de sécurité de 3:1, ce qui signifie que la résistance à la rupture doit être trois fois supérieure à la CMU pour tenir compte de l'accélération instantanée pendant le transport.

Conformité et certification mondiales

Zhangjiagang SMK MFG. Co., Ltd. est certifié ISO 9001, garantissant un système de gestion de la qualité de haut niveau. C'est Arrimage industriel les produits sont conformes à plusieurs normes internationales, y compris les certifications GS et brevets. L'entreprise est également auditée SMETA et a passé avec succès les inspections antiterroristes C-TPAT. Une telle conformité garantit que chaque Arrimage industriel dans leur réseau d'approvisionnement mondial répond aux exigences d'entrée strictes des marchés internationaux, fournissant des produits efficaces et de haute qualité dans le monde entier.

Composants de base et science des matériaux de l'arrimage industriel

Un performant Arrimage industriel Le système résulte de la synergie de plusieurs composants de précision. En tant que fabricant professionnel, Zhangjiagang SMK MFG. Co., Ltd. met en œuvre un contrôle qualité complet du processus, des matières premières aux produits finis, dans ses laboratoires d'essais internes.

Analyse des matériaux de sangle

La sangle est le principal élément porteur du Arrimage industriel . Différentes structures fibreuses déterminent ses limites physiques :

| Type de matériau | Taux d'allongement | Résistance aux UV | Adaptabilité environnementale | Application industrielle |

| Polyester | Très faible | Excellent | Résistant aux acides, non absorbant | Le premier choix pour Arrimage industriel dans le transport longue distance |

| Nylon | Élevé | Moyenne | La force diminue lorsqu’elle est mouillée | Convient pour une récupération absorbant les chocs, pas pour des attaches à long terme |

| Polypropylène | Moyen | Pauvre | Léger, résistant à la corrosion | Utilisé uniquement pour le regroupement léger et non critique |

| UHMWPE | Extrêmement faible | Supérieure | Élevé strength, cut-resistant | Solution haut de gamme pour les environnements extrêmement exigeants ou miniers |

Zhangjiagang SMK MFG. Co., Ltd. se concentre sur la torsion du fil à haute ténacité et la densité de tissage. Le tissage haute densité améliore non seulement le module de traction du Arrimage industriel mais améliore également sa résistance à l'abrasion de surface, prolongeant ainsi la durée de vie du produit dans des environnements logistiques difficiles.

Dispositifs de tension et quincaillerie métallique

Zhangjiagang SMK MFG. Co., Ltd. effectue des tests rigoureux de brouillard salin, de traction et de fatigue pour garantir que le matériel dans chaque Arrimage industriel le système est infaillible :

- Boucles à cliquet : Fabriqué en acier allié à haute résistance traité thermiquement. L'engagement des engrenages de précision offre un puissant avantage mécanique, garantissant le Arrimage industriel ne se desserre pas sous les vibrations à haute fréquence.

- Boucles à came : Conçu pour les travaux légers ou fragiles Arrimage industriel candidatures. Ils s'appuient sur des ressorts internes à haute tension pour se verrouiller, empêchant ainsi la déformation de la cargaison causée par une tension excessive.

- Raccords d'extrémité : Ceux-ci incluent des crochets doubles en J, des crochets plats, des anneaux en D et des raccords E-Track. Zhangjiagang SMK MFG. Co., Ltd. garantit que toutes les pièces métalliques sont zinguées ou revêtues de poudre pour une prévention supérieure de la rouille, ce qui les rend idéales pour une utilisation extérieure à long terme.

Classification de l'arrimage industriel dans les scénarios professionnels

Différentes exigences de charge et environnements d'exploitation dictent l'orientation de la conception d'un Arrimage industriel . Zhangjiagang SMK MFG. Co., Ltd. fournit des solutions personnalisées dans plusieurs secteurs clés, en s'appuyant sur plus de 20 ans d'expertise industrielle.

Transport à plat et logistique principale

Dans le camionnage lourd, Arrimage industriel des largeurs de 2 à 4 pouces sont standard. Ces applications nécessitent que les sangles aient une résistance extrême aux UV, car elles sont exposées à la lumière directe du soleil pendant de longues périodes. Si le matériau est de qualité inférieure, les rayons UV dégradent les chaînes moléculaires des fibres, provoquant la résistance à la rupture du matériau. Arrimage industriel se dégrader rapidement. La gamme SMK comprend des sangles d'arrimage robustes et des sangles de remorquage spécialement conçues pour ces rôles exigeants.

Fret aérien et conteneurs maritimes

Les environnements maritimes présentent des défis de corrosion élevée par brouillard salin. Pour ces cas, spécialisés Arrimage industriel les systèmes sont souvent équipés de composants en acier inoxydable 304 ou 316. Pour maximiser l'espace dans les conteneurs, ces sangles s'intègrent souvent aux systèmes E-Track, nécessitant une grande précision dimensionnelle dans les raccords d'extrémité. Zhangjiagang SMK MFG. Co., Ltd. maintient ces normes grâce à son réseau d’approvisionnement international efficace.

Sécurisation des chantiers de construction et des machines lourdes

Lors de la sécurisation des excavatrices ou des grues, le Arrimage industriel doit manipuler des surfaces rugueuses et des formes irrégulières. Le principal défi ici est l’abrasion localisée. Zhangjiagang SMK MFG. Co., Ltd. propose des sangles de qualité professionnelle avec une épaisseur renforcée et des manchons anti-abrasion en option pour garantir le Arrimage industriel n'est pas sectionné par les bords métalliques de la machinerie lourde.

Paramètres clés pour sélectionner le bon arrimage industriel

Comprendre les caractéristiques physiques de la cargaison est une condition préalable à la sélection d'un Arrimage industriel . Zhangjiagang SMK MFG. Co., Ltd. suggère de comparer les paramètres techniques suivants pour un contrôle optimal du fret :

| Paramètre | Gamme de spécifications | Logique de sélection |

| Largeur de la sangle | 1" (25 mm) à 4" (100 mm) | Des sangles plus larges répartissent la pression plus efficacement, protégeant ainsi les surfaces de chargement |

| Limite de charge (WLL) | 500 livres à 10 000 livres | La somme de la WLL doit généralement dépasser 50 % du poids de la cargaison pour gérer les charges dynamiques |

| Épaisseur de la sangle | 1,5 mm à 3,5 mm | L’épaisseur a un impact direct sur la résistance à l’usure ; 2,5 mm est recommandé pour l'industrie lourde |

| Modèle de couture | Couture multi-rangs automatisée | La disposition des coutures détermine la résistance du joint dans le Arrimage industriel |

| Personnalisation | Services d'OEM/ODM | Zhangjiagang SMK MFG. Co., Ltd. prend en charge les longueurs, les couleurs et l'impression personnalisées |

Procédures opérationnelles de sécurité : installation professionnelle d'arrimage industriel

Même la plus haute qualité au monde Arrimage industriel peut avoir une valeur de sécurité nulle s’il est mal installé. Zhangjiagang SMK MFG. Co., Ltd. met l'accent sur un fonctionnement standardisé pour garantir une efficacité et une sécurité maximales :

- Vérification du point d'ancrage : Avant de fixer le Arrimage industriel , confirmer la solidité du point d'ancrage sur le véhicule. Si l'ancre est plus faible que la sangle, elle peut échouer avant la sangle.

- Alignement des sangles : Assurer le Arrimage industriel reste plat lorsqu'il passe à travers le cliquet. Toute torsion provoque une répartition inégale de la tension, entraînant une fatigue précoce des fibres.

- Utilisation de protecteurs de bords : C'est le moyen le plus efficace de protéger votre Arrimage industriel . Placer des protections en plastique ou en caoutchouc sur les bords tranchants empêche la sangle d'être coupée sous tension.

- Gestion des tensions : Appliquez une force douce sur la poignée à cliquet. Une prétension excessive peut endommager la structure du chargement ou provoquer une déformation permanente du Arrimage industriel composants métalliques.

Normes de maintenance et de mise hors service pour l'arrimage industriel

Depuis un Arrimage industriel est un consommable de sécurité critique, des évaluations régulières du cycle de vie sont essentielles. Zhangjiagang SMK MFG. Co., Ltd. recommande de retirer immédiatement les produits si les signes suivants apparaissent lors de l'inspection :

- Coupes superficielles : Toute coupure ou déchirure dépassant 10 % de la largeur de la sangle rend Arrimage industriel peu fiable.

- Dommages chimiques : Durcissement, décoloration ou fragilité de la sangle, souvent provoqués par des fuites d'acide ou la proximité de sources de chaleur élevée.

- Panne matérielle : Poignées à cliquet pliées, axes usés ou mécanismes à ressort défaillants. La valeur fondamentale d'un Arrimage industriel est sa capacité de verrouillage ; si la mécanique tombe en panne, l'ensemble de l'unité doit être remplacé.

- Réparations illégales : N'essayez jamais de coudre un vêtement cassé Arrimage industriel vous-même. Aucune réparation hors usine ne peut garantir la WLL d'origine.

- Étiquettes manquantes : Si l'étiquette de chargement est manquante ou illisible, le Arrimage industriel est légalement considéré comme non classé et ne doit pas être utilisé pour le transport industriel.

FAQ

Q : Pourquoi Zhangjiagang SMK MFG. Co., Ltd. met l'accent sur les tests en interne ?

R : Les performances ne peuvent pas être jugées à l’œil nu. Nous utilisons des machines de traction universelles et des testeurs de brouillard salin pour simuler des conditions extrêmes. Seulement un Arrimage industriel qui réussit ces tests entre dans notre système d'approvisionnement, garantissant qu'il respecte 100 % de sa CMU nominale.

Q : Un arrimage industriel perdra-t-il sa tension par temps humide ?

R : Les sangles en nylon le feront, mais Zhangjiagang SMK MFG. Co., Ltd. utilise principalement du polyester de haute qualité. Le polyester a une absorption d'eau extrêmement faible, ce qui signifie que Arrimage industriel maintient une tension stable sous la pluie ou la neige.

Q : Pouvons-nous personnaliser les produits Arrimage industriel pour la marque de notre entreprise ?

R : Oui. Zhangjiagang SMK MFG. Co., Ltd. fournit des services OEM/ODM complets. Nous pouvons imprimer votre logo sur la sangle et personnaliser les couleurs ou les formes du matériel pour les adapter à des scénarios industriels spécifiques.

Q : Comment dois-je stocker une attache industrielle lorsqu'elle n'est pas utilisée ?

R : Ils doivent être roulés et stockés dans un environnement sec, aéré et sombre. Une exposition prolongée à des sols humides ou à la lumière directe du soleil réduira la durée de vie du Arrimage industriel .

Q : Les différentes couleurs d’Industrial Tie Down sont-elles uniquement esthétiques ?

R : Bien que les couleurs facilitent l'identification de la marque, les couleurs à haute visibilité (comme l'orange vif ou le vert citron) aident les opérateurs à localiser rapidement le produit. Arrimage industriel dans des environnements faiblement éclairés, réduisant ainsi le risque d’erreurs opérationnelles.

Q : Est-ce que Zhangjiagang SMK MFG. Co., Ltd. propose d'autres produits ?

R : Oui, notre gamme de produits comprend des sangles d'arrimage, des tendeurs élastiques, des sangles de remorquage, des élingues de levage, des palans et des accessoires 4x4, largement utilisés dans les secteurs du transport, de la logistique et de l'industrie.