Depuis sa création en 2002, Zhangjiagang SMK MFG. Co., Ltd. a spécialisé dans les produits de sécurisation et de contrôle de fret, avec plus 20 ans d'expérience en R&D et en exportation mondiale. L'entreprise est un fabricant en Chine de Attache de tente industrielle et une Fournisseurs personnalisés de Attache de tente industrielle, et exploite trois usines ainsi qu'un centre d'entrepôt à grande échelle, formant un réseau d'approvisionnement international efficace.

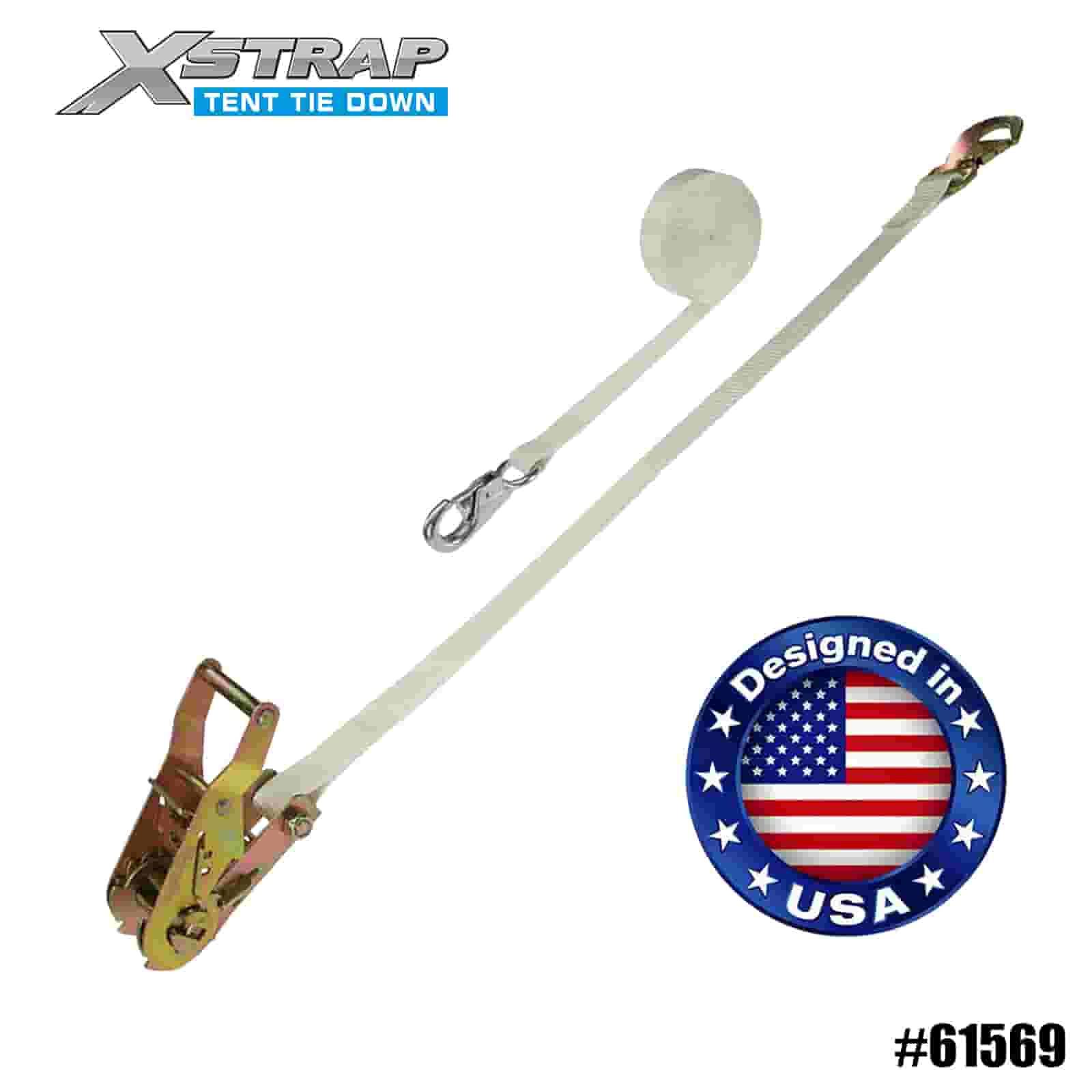

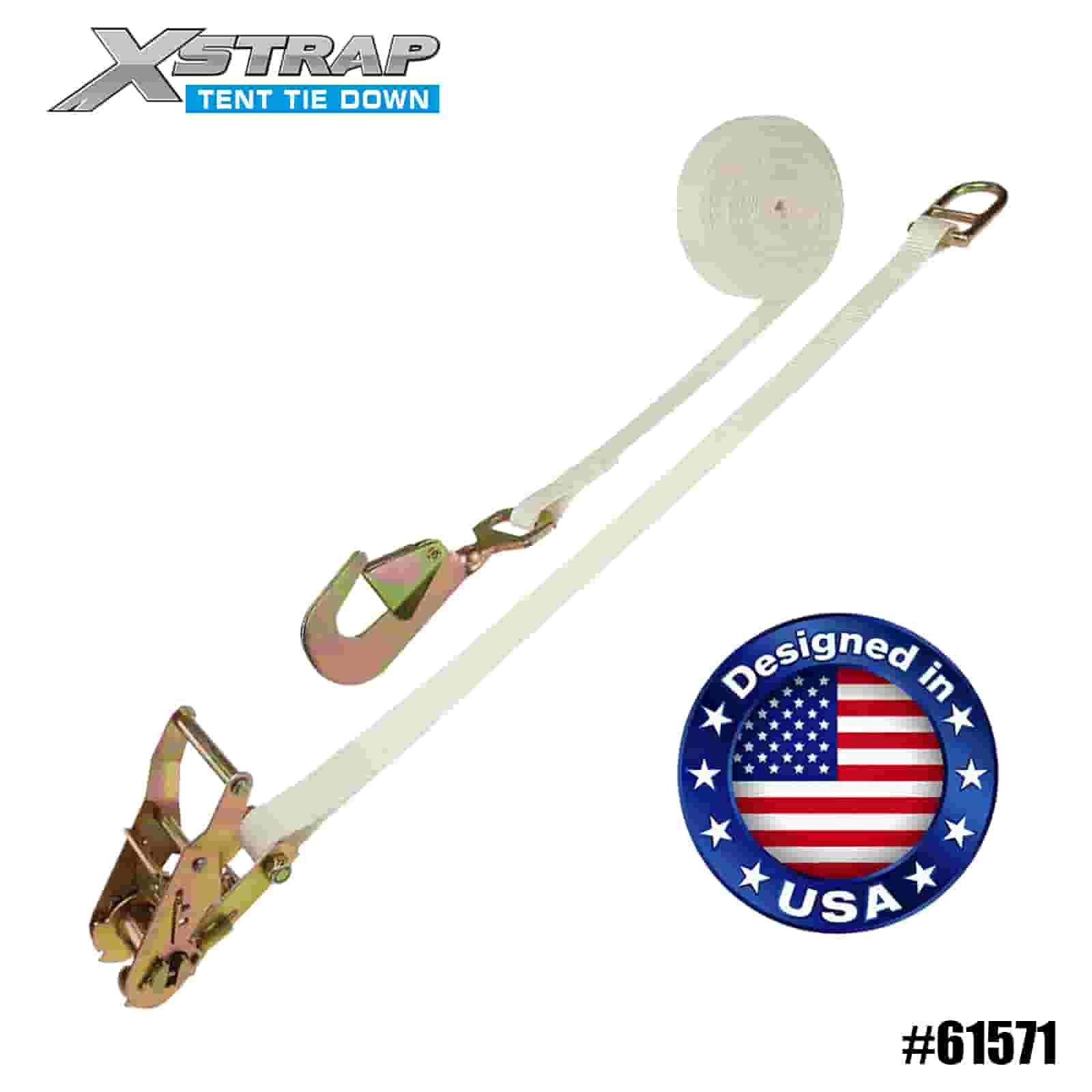

La gamme de produits de SMK comprend des sangles d'attachement, des cordons élastiques, des sangles de remorquage, des élingues de levage, des palans et des accessoires 4x4, largement utilisés dans les secteurs de transport, de logistique, de plein air et industriel. Sa marque interne XStrap jouit d'une forte reconnaissance sur les marchés mondiaux, aux côtés de flexible Services OEM / ODM pour les besoins personnalisés.

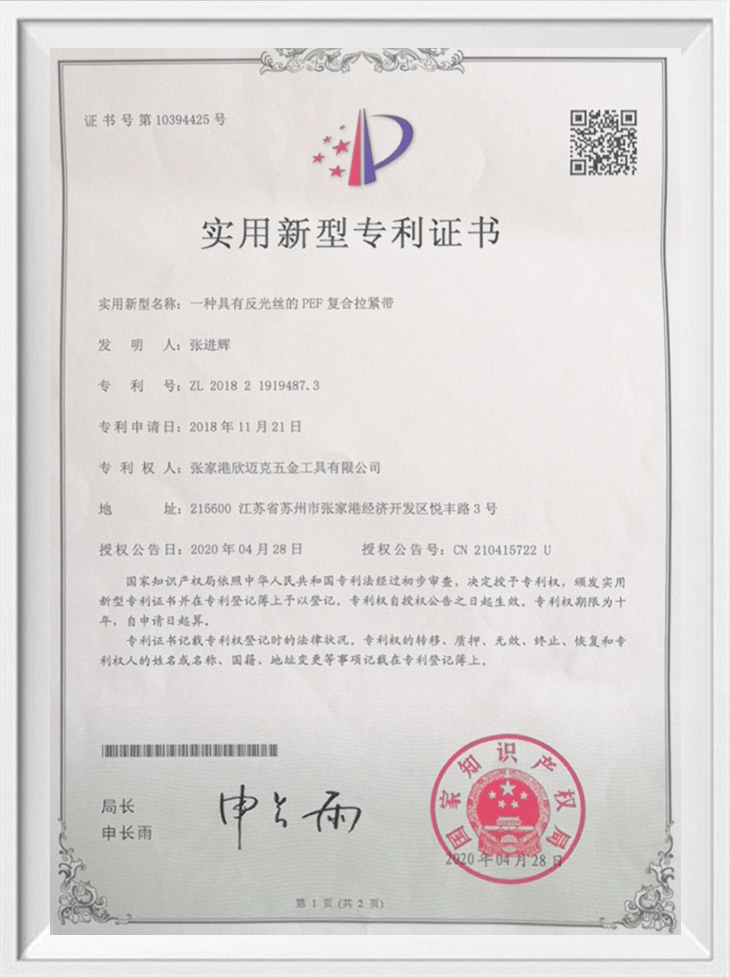

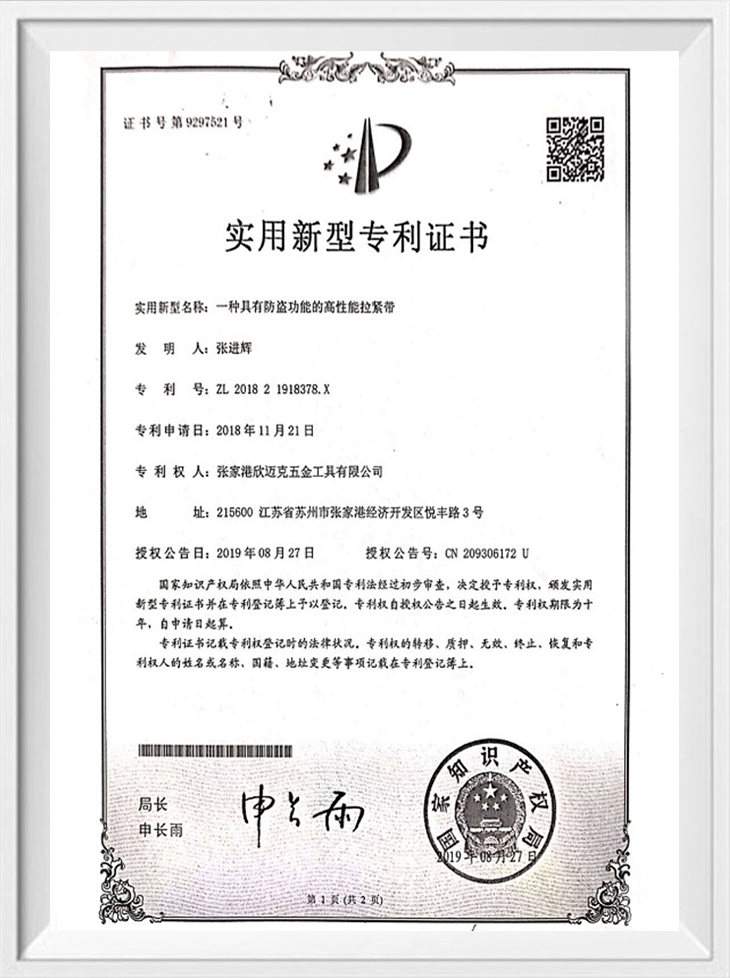

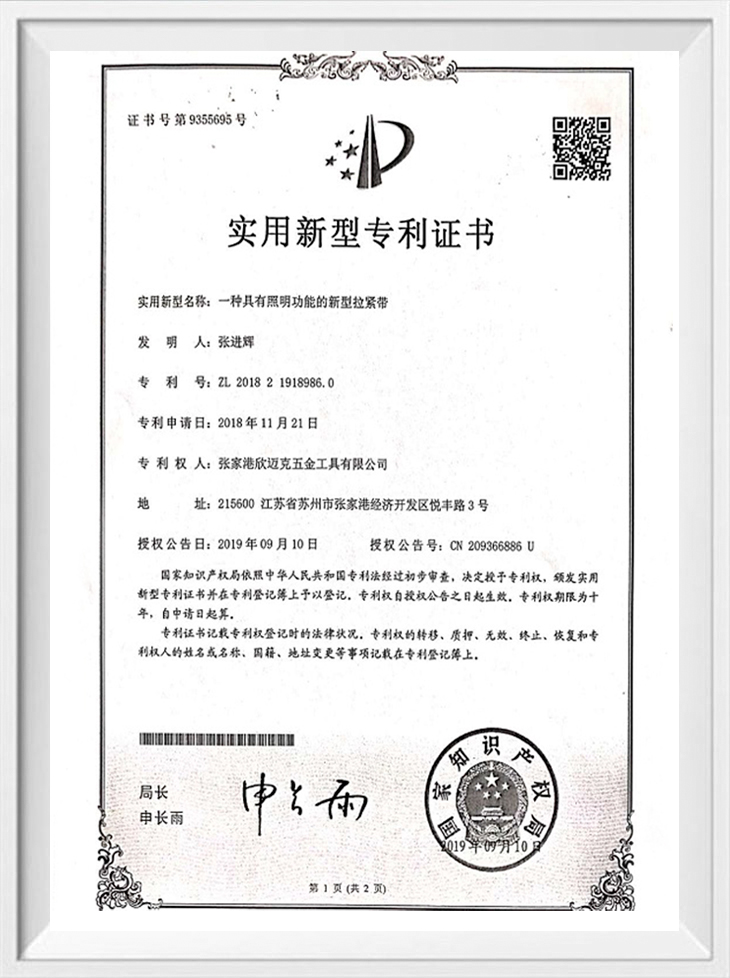

Avec plus de 8 000 m² d'espace de production, SMK est équipé de lignes automatisées avancées et de laboratoires de tests internes, assurant un contrôle de qualité complet des matières premières aux produits finis. La société est certifiée ISO 9001, Smeta audité et a passé des inspections antiterroristes C-TPAT et plusieurs certifications GS et brevets.

Pour l'avenir, SMK continuera de mettre à niveau ses systèmes de contrôle des cargaisons, de rester proches des besoins des clients et de fournir des produits et services efficaces de haute qualité dans le monde.

Produit

-

Nouveaux produits

- Solutions de plateau lisse

- Solutions pour l'intérieur de fourgon

-

Cordon d'arrimage et élastique polyvalent

-

Promotion d'arrimage à cliquet

-

Arrimage industriel

-

Arrimage de moto industrielle

-

Attache industrielle pour VTT UTV

-

Arrimage industriel en acier inoxydable

-

Attache de tente industrielle

-

Sangles de bateau

-

Sangle De Fixation À Cliquet À Charge Légère

-

Sangle De Fixation À Cliquet À Charge Standard

-

Sangle De Fixation À Cliquet À Charge Lourde

-

Sangle De Fixation À Cliquet À Charge Extra-Lourde

-

Cordon élastique

-

Promotion d'arrimage à cliquet

-

Solutions de transport et de remorquage de véhicules

-

Sangles De Transport De Véhicules

-

Sangles d'arrimage de voiture

-

Sangle de rechange pour arrimage de voiture

-

Sangles de panier de chariot de remorquage

-

Filets de roue

-

Sangles de récupération

-

Sangles et cordes de remorquage

-

Sangle de remorquage à cliquet et sangle de remorquage V Bridle

-

Extracteur et accessoires de remorquage Come Along

-

Sangles De Transport De Véhicules

-

Sangle

- Matériel d'arrimage

-

Attache et cordon élastique certifiés TUV&GS

-

Remorquage et gréement

-

4×4 tout-terrain et remorques

Vente en gros et fabrication de Attache de tente industrielle de qualité grand public

-

Face à la demande toujours croissante du marché, Xstrap Company a toujours maintenu un rythme d'expédition très efficace, garantissant les besoins des clients ave...

EN SAVOIR PLUS -

CCBEC(China (Shenzhen) Cross-Border E-Commerce Fair) is currently one of the largest and most influential professional exhibitions in the field of cross-border e-co...

EN SAVOIR PLUS -

Verified Supplier is the highest level membership on Alibaba.com. The platform conducts comprehensive verification—through both online document review and on-site f...

EN SAVOIR PLUS

Maîtriser l'arrimage de la tente : le guide ultime de la stabilité et de la sécurité

Dans le monde du camping extérieur, une tente est plus qu’un simple abri ; c'est la dernière ligne de défense contre les éléments. La clé pour garantir la solidité de cette défense réside dans l'application correcte d'un Attache pour tente système. Depuis sa création en 2002, Zhangjiagang SMK MFG. Co., Ltd. s'est spécialisé dans les produits d'arrimage des marchandises et de fixation extérieure. Avec plus de 20 ans d’expérience en R&D et en exportation mondiale, nous comprenons que dans des environnements complexes et à forte charge, la qualité de chaque point d’ancrage est vitale.

Pourquoi la tension est importante pour l'arrimage d'une tente

Un efficace Attache pour tente la stratégie implique plus que simplement attacher une corde à un pieu. La physique de l'équilibre des tensions détermine si une tente reste debout ou s'effondre pendant une tempête. Une tension appropriée répartit la force du vent uniformément sur le cadre et les piquets de la tente, protégeant ainsi le tissu délicat des déchirures. L'expertise technique accumulée par Zhangjiagang SMK MFG. Co., Ltd. dans le secteur de la sécurité du fret a été parfaitement appliqué à la fixation extérieure, garantissant que chaque point de tension reçoit un soutien scientifique, même en cas de rafales soutenues.

Mécanismes de protection en cas de conditions météorologiques extrêmes

À mesure que la vitesse du vent augmente, une tente génère une portance importante. Si le Attache pour tente la force est insuffisante ou l'angle est incorrect, les piquets peuvent facilement être retirés du sol. Les sangles d'arrimage et les cordons élastiques à haute résistance fabriqués via les lignes automatisées avancées de SMK sont conçus pour absorber les charges d'impact soudaines. Cet « équilibre dynamique » est essentiel pour empêcher les poteaux de tente de se casser en raison d'une pression inégale.

Améliorer le confort de vie

Au-delà de la sécurité, un supérieur Attache pour tente Le système améliore considérablement l'expérience de camping. Une tente lâche bat violemment au vent, créant un bruit qui perturbe le sommeil. En ajustant précisément le Attache pour tente lignes, vous pouvez garder la surface de la tente tendue, éliminant le bruit du vent et rendant votre exploration en plein air plus agréable.

Anatomie d'un système d'arrimage haute performance pour système de tente

Un complet Attache pour tente Le système se compose de plusieurs composants essentiels. En tant qu'entreprise certifiée ISO 9001, Zhangjiagang SMK MFG. Co., Ltd. maintient des normes strictes pour chaque paramètre matériel. Vous trouverez ci-dessous une comparaison du matériel requis pour construire un système hautes performances :

| Type de matériau | Force de rupture | Taux d'étirement | Résistance aux UV | Meilleur cas d'utilisation |

| Nylon | Élevé | 20% - 30% | Modéré | Camping général ; a besoin d’élasticité pour absorber les chocs |

| Polyester | Très élevé | Faible (moins de 5 %) | Excellent | Installation à long terme ; résiste à l'affaissement lorsqu'il est mouillé |

| Dyneema | Élevéest | Minime | Supérieure | Climats extrêmes ou besoins ultra légers |

Les cordons spécialisés produits par Zhangjiagang SMK MFG. Co., Ltd. sont testés dans des laboratoires internes pour garantir des performances stables sur diverses plages d’humidité et de température.

Piquets et ancres de tente

La stabilité ultime d'un Attache pour tente cela dépend des enjeux. Piquets en forme de V/à trois poutres conviennent aux sols meubles, offrant une plus grande résistance latérale. Piquets à vis sont idéaux pour le sable ou la neige, utilisant une plus grande surface pour garantir la Attache pour tente n'est pas sorti verticalement. Piquets en acier robuste sont conçus pour les sols durs, car le processus de fabrication SMK garantit que ces piquets ne se déforment pas sous un martelage intense.

Tendeurs

Le tendeur est le « centre de contrôle » du Attache pour tente . Les curseurs triangulaires en plastique sont légers et adaptés à la randonnée. Les tendeurs à 3 trous en alliage d'aluminium sont recommandés par SMK pour les environnements à haute altitude ou à basse température, car le métal ne devient pas cassant comme le plastique. Les verrous à boucle à came, empruntés aux systèmes de contrôle de chargement de SMK, permettent un serrage d'une seule main et constituent le choix préféré pour les grands camps de base. Attache pour tente configurations.

Noeuds essentiels dont chaque campeur a besoin pour attacher sa tente

Le matériel ne représente que la moitié de la bataille ; le cœur du fonctionnement pratique réside dans la manière dont vous connectez le cordon à l’ancre. En plus de 20 ans d'expérience chez Zhangjiagang SMK MFG. Co., Ltd. , nous avons constaté que de nombreuses défaillances se produisent non pas à cause d'une rupture de matériau, mais parce que les nœuds glissent sous l'effet des vibrations ou d'une pression constante.

Attelage à ligne tendue

C'est l'étalon-or pour un Attache pour tente . Il s'agit d'un attelage à friction réglable, parfait pour relier les haubans de tente aux piquets. Il permet d'ajuster la tension sans dénouer le nœud. Il maintient fermement la ligne principale sous tension mais glisse facilement lorsque la tension est relâchée, ce qui est crucial pour s'adapter à l'expansion du cordon causée par les changements de température ou d'humidité.

Bouline

Connu sous le nom de « roi des nœuds », il est utilisé dans un Attache pour tente pour créer une boucle fixe et antidérapante au bout d'un cordon. Il sert à attacher la corde aux points d’haubanage de la tente. Il ne glissera pas et ne se pliera pas sous de lourdes charges et est facile à détacher après la tâche. Les données du laboratoire SMK montrent que le Bowline conserve environ 65 à 70 % de la résistance à la rupture d'origine du cordon.

Attelage de camion

En tant qu'experts en contrôle du fret, Zhangjiagang SMK MFG. Co., Ltd. recommande fortement ce nœud lorsqu'une tension extrême est requise. Il utilise un principe de poulie pour offrir un avantage mécanique de 3 : 1. Lorsque vous devez tirer un grand auvent ou Attache pour tente système aussi serré qu'une corde de guitare, ce nœud est le seul choix.

Attelage clou de girofle

Ce nœud sécurise rapidement une corde temporairement à un objet cylindrique comme un poteau de tente ou une branche à proximité. Il ne convient qu'à une tension constante dans une seule direction. Si la direction de la force change fréquemment, il est conseillé d'utiliser des sandows SMK pour absorber les changements dans la direction. Attache pour tente configuration.

Stratégies avancées pour un arrimage sécurisé de la tente dans des conditions venteuses

Face à des vents violents, les méthodes conventionnelles échouent souvent. Zhangjiagang SMK MFG. Co., Ltd. suggère les stratégies avancées suivantes pour renforcer votre Attache pour tente système.

Répartition des forces : la règle d'or des 45 degrés

L'angle entre le cordon et le sol est critique pour un Attache pour tente .

| Angle | Performances de stabilité | Principe de physique |

| Moins de 30 degrés | Pauvre | Trop de levier ; retire facilement le piquet horizontalement. |

| 45 degrés (recommandé) | Excellent | La force est répartie uniformément entre les plans vertical et horizontal. |

| Plus de 60 degrés | Foire | Ne parvient pas à contrecarrer efficacement la force du vent latéral. |

Méthode de jalonnement en V

Lorsqu'un seul piquet ne peut pas supporter la charge de vent, utilisez la méthode V-Staking recommandée par les ingénieurs SMK. Connectez deux cordons à partir d'un seul Attache pour tente point d’ancrage à deux piquets distincts à un angle de 45 degrés. Cette structure disperse considérablement la pression ponctuelle.

Coordonner le renforcement externe et interne

Au-delà de l'extérieur Attache pour tente , vous pouvez utiliser des sangles à cliquet robustes SMK pour renforcer le cadre de la tente à l'intérieur par temps extrême. Cette synergie entre soutien interne et tension externe peut augmenter la résistance au vent d’une tente de plus de 30 %.

Arrimage spécifique au terrain pour les techniques de tente

Différents paysages nécessitent des techniques de fixation très différentes. Zhangjiagang SMK MFG. Co., Ltd. utilise son espace de production de 8 000 m² et ses laboratoires d'essais pour simuler divers environnements extrêmes pour Attache pour tente efficacité.

Sable et neige (Ancre Deadman)

Dans les médias doux, les enjeux standards sont inutiles. Vous devez utiliser la technique Deadman : attachez une sangle SMK haute résistance à une branche ou à une douve des neiges, enterrez-la horizontalement à 30-50 cm de profondeur et tassez la surface. Ceci Attache pour tente La méthode repose sur le poids des morts-terrains pour générer une friction.

Terrain rocheux dur (Big Rock, Little Rock)

Lorsque vous ne pouvez pas enfoncer un pieu, utilisez l’effet de levier et la gravité. Placez une petite boucle du Attache pour tente ligne sous un rocher plus petit. Placez un rocher massif au-dessus du plus petit rocher et de la corde, en utilisant la friction entre les rochers pour garantir que la ligne ne glisse pas.

Forêt et terres boisées

Utilisez des piliers naturels. Zhangjiagang SMK MFG. Co., Ltd. produit des élingues et des sangles de levage dotées de manchons de protection qui peuvent s'enrouler autour des troncs d'arbres, fournissant ainsi un puissant Attache pour tente ancrer sans endommager l’écorce.

Erreurs courantes à éviter avec votre attache pour tente

Même avec le meilleur matériel, une installation incorrecte peut compromettre un Attache pour tente . Zhangjiagang SMK MFG. Co., Ltd. a résumé les erreurs techniques les plus courantes sur la base des commentaires des clients mondiaux :

Surtension

De nombreux campeurs pensent que plus serré est toujours mieux, mais c'est une idée fausse. Un serrage excessif d'un Attache pour tente peut endommager la fermeture éclair là où le tissu est étiré jusqu'à sa limite, et déchirer les coutures là où une surcharge constante crée des microfissures dans les revêtements PU. Les cordes doivent être tendues mais pas rigides, laissant une légère élasticité pour amortir les rafales de vent.

Ignorer l'angle d'entrée de la mise

C'est la cause la plus fréquente de Attache pour tente échec. Enfoncer le piquet verticalement ou en l'inclinant vers la tente permet de retirer facilement le piquet. Le piquet doit toujours être enfoncé à un angle de 90 degrés par rapport à la tension du cordon, ce qui signifie qu'il doit s'éloigner de la tente.

Manque de visibilité

En basse lumière, dans l'obscurité Attache pour tente les lignes sont des risques de trébuchement dangereux. Trébucher provoque des blessures et peut déchirer instantanément les points de fixation de la tente. Utilisez des cordes SMK tissées avec des traceurs réfléchissants pour une haute visibilité pour sécuriser votre Attache pour tente périmètre.

Entretien et entretien de votre attache pour équipement de tente

Pour assurer votre Attache pour tente le système ne tombe pas en panne à un moment critique, un entretien régulier est essentiel. Zhangjiagang SMK MFG. Co., Ltd. recommande la routine de soins suivante :

Nettoyage des sangles et des cordons

Pendant l'utilisation, Attache pour tente les lignes collectent la boue, le sel et la sève. Le grain séché agit comme du papier de verre, abrasant les fibres internes et réduisant la résistance à la rupture. Laver à l'eau tiède et au savon neutre ; n'utilisez jamais de produits chimiques agressifs sur votre Attache pour tente équipement.

Contrôle de la corrosion du matériel

Les piquets et tendeurs sont souvent en contact avec un sol humide. Nos composants métalliques sont généralement galvanisés ou anodisés pour une résistance supérieure à la corrosion. Séchez toutes les pièces métalliques après un voyage et appliquez une petite quantité de lubrifiant sur les pièces mobiles pour garantir un bon fonctionnement. Attache pour tente opération la prochaine fois.

Stockage approprié

Les rayons UV sont les ennemis des fibres synthétiques. Même avec les certifications SMK résistantes aux UV, rangez votre équipement dans un endroit frais et sombre. Ne scellez jamais un Attache pour tente kit lorsqu'il est humide, car la moisissure dégradera rapidement la structure du tissu.

FAQ

De combien de points d’arrimage ai-je réellement besoin pour ma sécurité ?

Cela dépend de la conception de la tente. En règle générale, outre les quatre coins, chaque point d'haubanage du côté au vent doit être utilisé comme point d'ancrage. Attache pour tente ancre. Lors des tests de charge SMK, la dispersion des points de force a considérablement augmenté la résistance globale au vent.

Puis-je utiliser des sangles de remorquage pour une tente puisque vous fabriquez également des accessoires 4x4 ?

Tandis que Zhangjiagang SMK MFG. Co., Ltd. produit des sangles de remorquage incroyablement solides, elles sont trop lourdes et n'ont pas le réglage précis nécessaire pour un Attache pour tente . Nous vous recommandons d'utiliser nos cordons légers et à haute résistance spécialement conçus pour une utilisation en extérieur.

Pourquoi mes haubans se détachent-ils après la pluie ?

Il s'agit d'une propriété physique des matériaux. Le nylon se dilate lorsqu'il absorbe l'eau. Si vous êtes dans une région pluvieuse, choisissez Attache pour tente lignes en polyester de SMK, car elles ont un taux d'absorption d'eau plus faible et maintiennent une tension constante.

Que se passe-t-il si la boucle de fixation de ma tente se déchire ?

Placez une petite pierre propre ou un bouchon de bouteille derrière le tissu et attachez votre Attache pour tente cordon autour du tissu groupé et de la pierre. Cette ancre de secours fonctionne efficacement à la rigueur.

Assurer la fiabilité à long terme de votre abri

Choisir des produits parmi Zhangjiagang SMK MFG. Co., Ltd. signifie choisir un fabricant avec plus de 20 ans d'expérience en matière de chaîne d'approvisionnement internationale, d'audits SMETA et de conformité C-TPAT. Que ce soit sur une crête accidentée ou dans une vallée humide, un scientifique Attache pour tente Le système offre la tranquillité d’esprit d’une maison.

| Dimension d'évaluation | Norme recommandée SMK | Impact sur l'arrimage de la tente |

| Épaisseur de la sangle | 1,0 mm - 2,5 mm | Détermine la limite de résistance à l'abrasion |

| Matériau du tendeur | Aluminium 6061 T6 ou plastique renforcé | Assure la résistance mécanique aux températures extrêmes |

| Résistance aux UV Rating | ISO 105-B02 Niveau 4 | Prolonge la durée de vie sous la lumière directe du soleil |

| Contrôle qualité | Tests internes complets | Élimine les risques potentiels pour la sécurité dès le départ |