Depuis sa création en 2002, Zhangjiagang SMK MFG. Co., Ltd. a spécialisé dans les produits de sécurisation et de contrôle de fret, avec plus 20 ans d'expérience en R&D et en exportation mondiale. L'entreprise est un fabricant en Chine de Arrimage de moto industrielle et une Fournisseurs personnalisés de Arrimage de moto industrielle, et exploite trois usines ainsi qu'un centre d'entrepôt à grande échelle, formant un réseau d'approvisionnement international efficace.

La gamme de produits de SMK comprend des sangles d'attachement, des cordons élastiques, des sangles de remorquage, des élingues de levage, des palans et des accessoires 4x4, largement utilisés dans les secteurs de transport, de logistique, de plein air et industriel. Sa marque interne XStrap jouit d'une forte reconnaissance sur les marchés mondiaux, aux côtés de flexible Services OEM / ODM pour les besoins personnalisés.

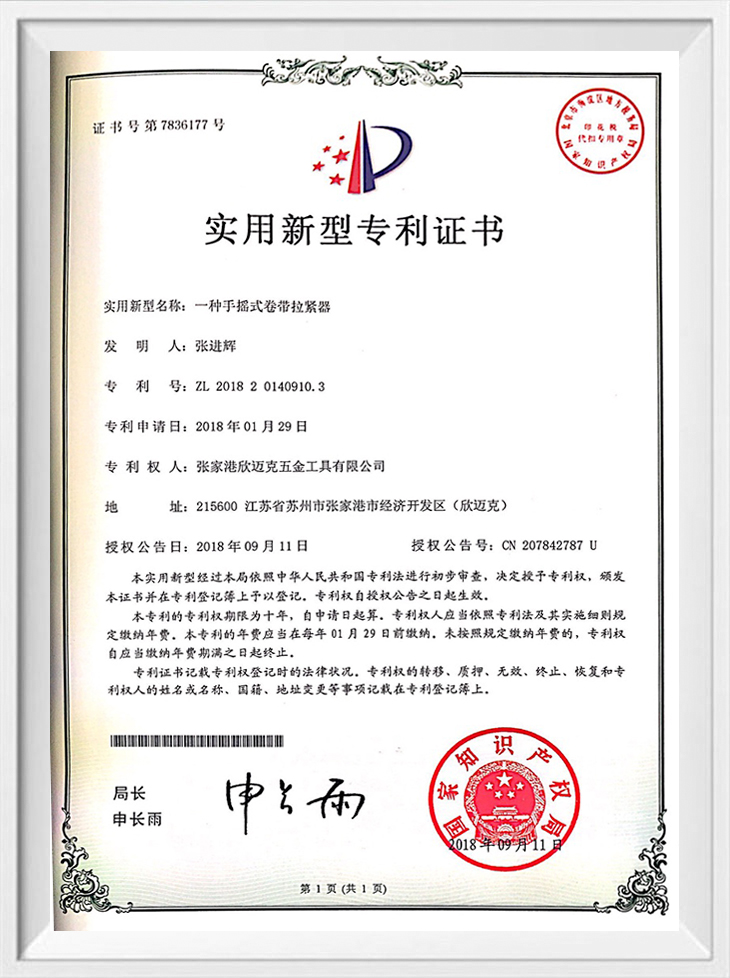

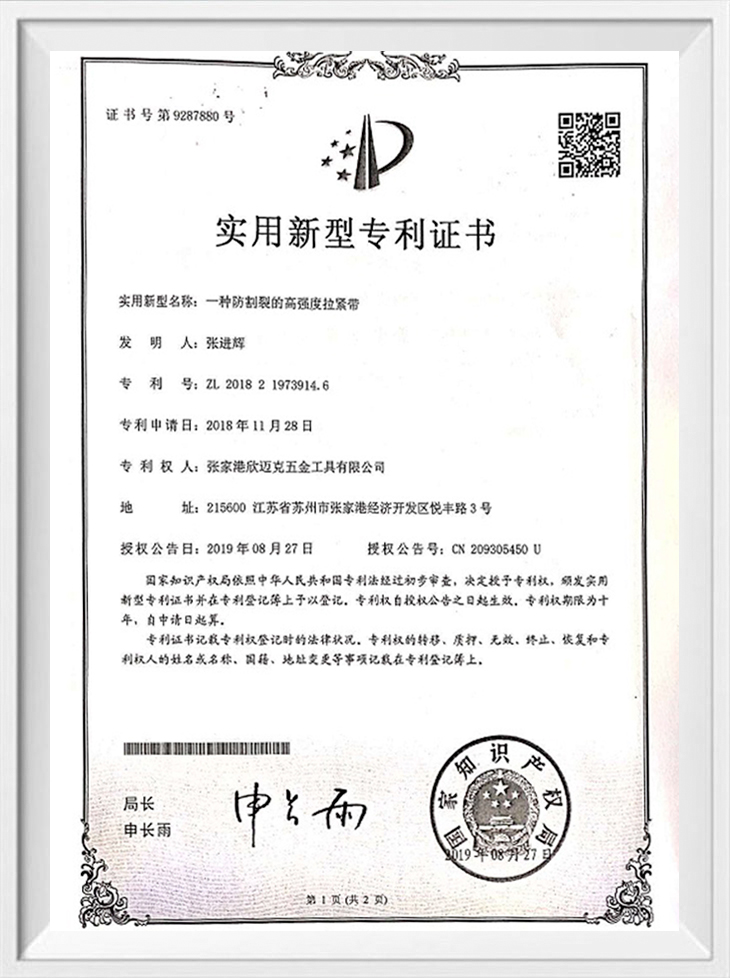

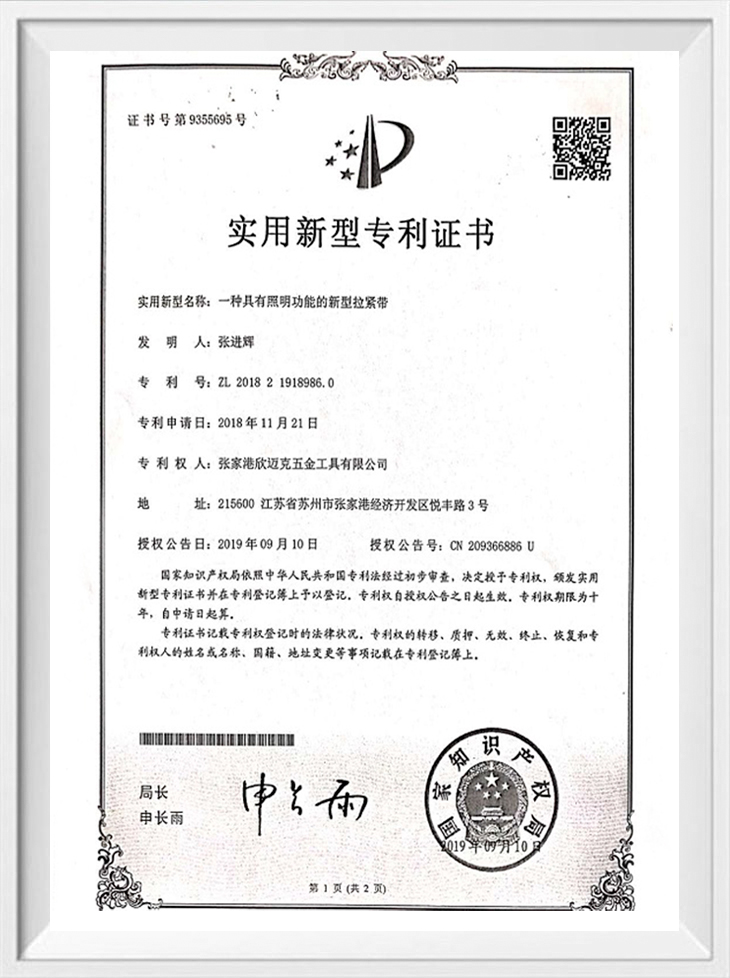

Avec plus de 8 000 m² d'espace de production, SMK est équipé de lignes automatisées avancées et de laboratoires de tests internes, assurant un contrôle de qualité complet des matières premières aux produits finis. La société est certifiée ISO 9001, Smeta audité et a passé des inspections antiterroristes C-TPAT et plusieurs certifications GS et brevets.

Pour l'avenir, SMK continuera de mettre à niveau ses systèmes de contrôle des cargaisons, de rester proches des besoins des clients et de fournir des produits et services efficaces de haute qualité dans le monde.

Produit

-

Nouveaux produits

- Solutions de plateau lisse

- Solutions pour l'intérieur de fourgon

-

Cordon d'arrimage et élastique polyvalent

-

Promotion d'arrimage à cliquet

-

Arrimage industriel

-

Arrimage de moto industrielle

-

Attache industrielle pour VTT UTV

-

Arrimage industriel en acier inoxydable

-

Attache de tente industrielle

-

Sangles de bateau

-

Sangle De Fixation À Cliquet À Charge Légère

-

Sangle De Fixation À Cliquet À Charge Standard

-

Sangle De Fixation À Cliquet À Charge Lourde

-

Sangle De Fixation À Cliquet À Charge Extra-Lourde

-

Cordon élastique

-

Promotion d'arrimage à cliquet

-

Solutions de transport et de remorquage de véhicules

-

Sangles De Transport De Véhicules

-

Sangles d'arrimage de voiture

-

Sangle de rechange pour arrimage de voiture

-

Sangles de panier de chariot de remorquage

-

Filets de roue

-

Sangles de récupération

-

Sangles et cordes de remorquage

-

Sangle de remorquage à cliquet et sangle de remorquage V Bridle

-

Extracteur et accessoires de remorquage Come Along

-

Sangles De Transport De Véhicules

-

Sangle

- Matériel d'arrimage

-

Attache et cordon élastique certifiés TUV&GS

-

Remorquage et gréement

-

4×4 tout-terrain et remorques

Vente en gros et fabrication de Arrimage de moto industrielle de qualité grand public

Informations à mettre à jour

-

Face à la demande toujours croissante du marché, Xstrap Company a toujours maintenu un rythme d'expédition très efficace, garantissant les besoins des clients ave...

EN SAVOIR PLUS -

CCBEC(China (Shenzhen) Cross-Border E-Commerce Fair) is currently one of the largest and most influential professional exhibitions in the field of cross-border e-co...

EN SAVOIR PLUS -

Verified Supplier is the highest level membership on Alibaba.com. The platform conducts comprehensive verification—through both online document review and on-site f...

EN SAVOIR PLUS

Pourquoi un bon arrimage pour les motos est au cœur de la sécurité des transports

Dans le monde du transport moto, la sécurité est toujours la préoccupation première. Que vous vous rendiez sur la piste pour une course de week-end ou que vous déménagiez votre bien le plus précieux dans une nouvelle maison, choisissez et utilisez correctement un produit de haute qualité. Attache pour moto est la clé pour garantir que votre véhicule reste intact. Une moto n’est pas une charge statique ; son centre de gravité unique et son système de suspension le rendent très sensible aux forces d'inertie pendant le transport.

Lorsqu'un véhicule de transport rencontre un freinage d'urgence, des virages serrés ou des accidents de la route, un vélo non sécurisé sans support robuste Attache pour moto Le système subira un mouvement alternatif incontrôlé de ses amortisseurs. Ce mouvement peut faire glisser les sangles, incliner le vélo ou entraîner des rayures coûteuses sur le carénage et une déformation du cadre. Dans des cas extrêmes, la moto peut même se détacher de la plateforme, provoquant ainsi de graves accidents de la route.

En tant qu'experts du secteur possédant plus de 20 ans d'expérience dans l'arrimage et le contrôle des marchandises, Zhangjiagang SMK MFG. Co., Ltd. comprend tous les détails physiques de la fixation de la moto. Depuis notre création en 2002, nous nous sommes concentrés sur la R&D et le contrôle qualité pour produire Attache pour moto produits capables de résister à des charges dynamiques extrêmes. En comprimant scientifiquement la suspension et en établissant un support multipoint, nos solutions sont conçues pour compenser les impacts physiques, offrant ainsi une garantie solide pour chaque trajet.

Comprendre les différents types d'arrimage pour moto et leurs applications

Pour répondre aux besoins des différents modèles et environnements de vélos, Attache pour moto les conceptions ont évolué vers plusieurs formes spécialisées. Zhangjiagang SMK MFG. Co., Ltd. utilise des lignes automatisées avancées dans son espace de production de 8 000 m² pour fabriquer ces outils avec précision.

Tableau de comparaison des produits de base

| Tapez | Mécanisme de verrouillage | Avantages | Utilisation recommandée |

| Sangles à cliquet | Tension mécanique des engrenages | Fournit une tension maximale ; ne se desserrera pas une fois verrouillé | Croiseurs lourds, vélos de tourisme, transports longue distance |

| Sangles à boucle à came | Morsure de pression à ressort | Extrêmement rapide et facile à utiliser ; serrage à une main | Motos tout-terrain, vélos de rue légers, courts trajets fréquents |

| Boucles douces | Conception de boucle de sangle | Empêche les crochets métalliques de toucher le vélo ; protège la peinture | Toutes les motos (utilisées comme accessoire auxiliaire) |

Sangles à cliquet : Ce type de Attache pour moto utilise un principe de levier mécanique. En pompant la poignée, la sangle peut être tendue jusqu'à un degré de tension élevé. Pour les motos lourdes, la stabilité structurelle assurée par les sangles à cliquet est irremplaçable.

Sangles à boucle à came : Ce sont les favoris des pilotes tout-terrain. Parce que les motos tout-terrain ont un long débattement de suspension et un poids léger, utilisant une boucle à came Attache pour moto permet une fixation rapide sans risque de serrage excessif et d'endommagement des joints de fourche délicats.

La nécessité des boucles souples : Accrocher des extrémités métalliques directement sur le guidon laisse souvent des rayures. En utilisant des boucles souples, vous pouvez d'abord enrouler la sangle autour du cadre ou des arbres triples, puis connecter les Attache pour moto accrochez-vous à la boucle.

Spécifications clés lors du choix d’une attache pour moto

Comprendre les paramètres professionnels est une condition préalable à la sécurité. Zhangjiagang SMK MFG. Co., Ltd. maintient des laboratoires de tests internes pour garantir que chaque lot de Attache pour moto répond aux normes de performance internationales.

Limite de charge de travail (WLL) par rapport à la résistance à la rupture (BS)

Résistance à la rupture : Force maximale que la sangle ou le mécanisme peut supporter avant une défaillance dans un environnement de laboratoire. Limite de charge de travail (CMU) : Généralement 1/3 de la résistance à la rupture. Pour un Attache pour moto , il est recommandé que la CMU combinée des sangles dépasse le poids de la moto d'au moins 1,5 fois.

Matériau et largeur de la sangle

La plus haute qualité Attache pour moto les produits utilisent du polyester haute ténacité. Sangle de 1 pouce (25 mm) offre une grande flexibilité, adaptée à la plupart des vélos standards, tout en Sangle de 1,5 à 2 pouces (38 mm à 50 mm) offre une plus grande surface pour réduire la pression locale sur les points d'arrimage, idéal pour les machines ultra-lourdes.

Sécurité du crochet

Le Attache pour moto solutions apportées par Zhangjiagang SMK MFG. Co., Ltd. comportent souvent des crochets avec des loquets de sécurité. Cette conception empêche le crochet de se détacher du point d'ancrage si la suspension se comprime momentanément lors d'une forte bosse, provoquant un relâchement temporaire de la sangle.

Préparation : Trouver les points d'ancrage dorés sur votre moto

Avant d'installer un Attache pour moto , l’identification des points forts structurels est essentielle. Des points incorrects peuvent entraîner une instabilité ou des dommages aux composants.

Points d'ancrage avant

Arbres triples : L'un des emplacements les plus stables. Envelopper le Attache pour moto autour du té inférieur évite les carénages plastiques fragiles. Base du guidon : Si les barres sont solides et non montées sur du caoutchouc, elles peuvent servir de point, bien que des boucles souples soient fortement recommandées ici.

Points de stabilité arrière

Sous-châssis : Cherchez le squelette métallique sous le siège. Supports de repose-pieds passager : La plupart des supports sont fabriqués en acier robuste ou en fonte d'aluminium, ce qui les rend parfaits pour un Attache pour moto pour éviter le balancement de l'arrière.

Zones à éviter

Lorsque vous utilisez un Attache pour moto , reste à l'écart Conduites de frein hydrauliques car la compression peut entraîner une défaillance des freins, Bords de carénage en plastique qui peut être tranché par haute tension, et Faisceaux de câbles où la friction peut provoquer des courts-circuits électriques.

Guide étape par étape : Comment installer correctement une attache pour moto

En tant que fournisseur professionnel de contrôle du fret, Zhangjiagang SMK MFG. Co., Ltd. recommande le processus standardisé suivant pour le déploiement de votre Attache pour moto système :

Positionnement et blocage des roues : Faites rouler le vélo sur la plate-forme, en utilisant de préférence une cale de roue pour fournir un support latéral et maintenir le vélo droit pendant que vous travaillez.

Fixation des sangles avant : Placez symétriquement deux Attache pour moto unités de chaque côté. Demandez à un assistant de maintenir le vélo à la verticale pendant que vous fixez les crochets. Visez un angle de 45 degrés pour fournir à la fois une pression vers le bas et une stabilité latérale.

Compression de la suspension : Tirez sur l'avant du vélo tout en serrant le Attache pour moto . Ciblez environ 50 % du débattement de la suspension. N'enfoncez pas les fourches, car une certaine marge de mouvement protège les joints d'huile des pics de pression internes.

Sécurisation de l'arrière : Installez deux supplémentaires Attache pour moto unités à l'arrière. Ceux-ci ne sont pas destinés à exercer une forte pression vers le bas, mais à empêcher la roue arrière de sauter ou de glisser latéralement pendant les virages.

Gestion de l'excès de sangle : Zhangjiagang SMK MFG. Co., Ltd. vous rappelle de ne jamais laisser l'excès de sangle flotter au vent. Pliez et attachez les queues pour éviter qu'elles ne s'emmêlent dans les roues ou ne fouettent contre la peinture.

Techniques spécialisées pour différents types de motos

Différentes motos nécessitent une logique spécifique lors de l'application d'un Attache pour moto . Basé sur plus de 20 ans d'expérience OEM/ODM, Zhangjiagang SMK MFG. Co., Ltd. suggère :

Motos sportives : Parce que le cadre est souvent caché par des carénages, l'utilisation de harnais de guidon spécialisés en conjonction avec un Attache pour moto est la meilleure stratégie.

Croiseurs lourds : Lese bikes are heavy with a low center of gravity. Use wider ratchet-style Attache pour moto unités et donner la priorité à la stabilisation arrière pour empêcher le poids massif de se déplacer vers l’arrière lors de l’accélération.

Motos tout-terrain : Lese have immense suspension travel. It is highly recommended to use a fork brace between the front tire and the fender. This allows the Attache pour moto doit être bien serré sans exercer de pression excessive sur les ressorts et les joints de fourche.

Protocole d'inspection dynamique pendant le transport

L'installation n'est pas la fin de la tâche. Les facteurs environnementaux affectent la tension d'un Attache pour moto .

Le 5-Mile Check: Après les premiers kilomètres, arrêtez-vous et inspectez les sangles. Les premières vibrations de la route permettent au vélo de s'installer, ce qui se traduit souvent par une légère baisse de tension de la sangle.

Conditions météorologiques humides : Si vous conduisez sous la pluie, la sangle en polyester peut s'étirer légèrement lorsqu'elle est mouillée. Vous devez resserrer votre Attache pour moto pour compenser.

Arrêts longue distance : Prenez l'habitude de vérifier toutes les boucles et sangles à la recherche de signes de friction ou de desserrage chaque fois que vous vous arrêtez pour faire le plein ou vous reposer.

Entretien et stockage : prolonger la durée de vie de votre attache pour moto

Les outils de qualité nécessitent des soins appropriés. Zhangjiagang SMK MFG. Co., Ltd. , en tant qu'entreprise certifiée ISO 9001, vous propose l'entretien suivant pour votre Attache pour moto :

Nettoyage régulier : Après le transport, lavez le sel de déneigement ou l’huile avec de l’eau propre et séchez à l’air. Les cristaux de sel peuvent agir comme de minuscules scies entre les fibres, réduisant ainsi la résistance du Attache pour moto .

Lubrification du mécanisme : Appliquez de temps en temps une petite quantité de lubrifiant sur les pièces mobiles du cliquet pour garantir un fonctionnement fluide.

Stockage approprié : Rangez votre Attache pour moto dans un endroit frais et sec. Les rayons UV sont le plus grand ennemi des fibres de polyester ; une exposition prolongée au soleil peut rendre la sangle fragile et dangereuse.

FAQ concernant l'arrimage pour moto

Puis-je sécuriser mon vélo avec seulement deux sangles ?

Même si cela peut paraître suffisant pour des vélos légers sur de courts trajets, nous recommandons toujours un système à quatre points. Les deux arrière Attache pour moto les unités agissent comme une redondance de sécurité vitale contre les glissières latérales.

Comment savoir quand il est temps de remplacer mes sangles ?

Zhangjiagang SMK MFG. Co., Ltd. recommande de remplacer tout Attache pour moto qui présente un effilochage sur 10 % de sa largeur, de graves taches chimiques ou si le mécanisme à cliquet montre des signes de rouille ou de déformation.

Est-ce que garder le vélo attaché pendant la nuit endommagera la suspension ?

Une compression modérée (environ 50 %) est généralement sans danger pendant de courtes périodes. Cependant, pour un stockage à long terme, il est préférable d'utiliser une béquille centrale et de desserrer la Attache pour moto tensions.

Pourquoi mes sangles émettent-elles un fort sifflement à grande vitesse ?

Ceci est dû aux vibrations à haute fréquence du vent. Pour résoudre ce problème, faites une simple torsion dans les longues sections du Attache pour moto sangle avant de la serrer. Cela interrompt le flux d’air et élimine le bruit.

En choisissant une qualité professionnelle Attache pour moto produits de Zhangjiagang SMK MFG. Co., Ltd. , vous gagnez bien plus que de simples sangles ; vous bénéficiez de la tranquillité d'esprit que procure deux décennies d'expertise dans l'industrie. Notre réseau d'approvisionnement mondial et nos certifications GS rigoureuses garantissent que votre moto reste stable à chaque kilomètre du trajet.